- Introduction

- What is a SAR and why does it produce "kickback"?

- Input stage spice model

- Sampling sequence

- Ideal voltage source

- Thermistor, voltage errors

- OPAMP buffer, but still has voltage spikes

- Jumper wire

- The solution for SAR, and how it works.

- Microcontroller analog input with built-in resistor.

- Some concluding words and suggestions

- Professional circuits, custom designs and support

- Step 1: On the leading edge of the clock pulse, S1 closes and connects the capacitor C1 to the input.

- Step 2: C1 now rapidly draws charge until it reaches the voltage presented at the input.

- Step 3: On the trailing edge of the clock, S1 opens to disconnect C1 from the input, and S2 closes.

- Please be sure to check out the professionally designed instrument circuits at The SPI Instrumentation Project. There you will find some really useful stuff for your lab.

- If you would like us to do a custom project for you, please write me (click here).

- And don't forget to donate. Your contribution supports open science by helping use make doing science more accessible.

1. Introduction

This is about using an analog input. As it turns out there are important differences between (a) the analog input you have in an Arduino or Teensy, or other micronctroller (MCU) cards, (b) an input board that you might connect to your MCU card over I2C or SPI, and (c) a bare ADC. To understand what is going on and how to make good measurements with whatever you have, we need start by understanding the bare ADC and how it is normally used. Measurement is a large topic with many sophisticated details and sub-topic areas, different kinds of noise, higher level measurement strategies, calibration, and etc. Here we take up the prerequisite, reliably getting faithful readings from an analog input. Let's begin.

"All the ADCs are flakey!"

It is a common scenario, you buy an inexpensive circuit or sensor, even something as simple as a thermistor, connect it to the analog input of your Arduino, and the readings seem off or not reproducible. And, you soon find that you are not alone. There are lots of posts on forums asking why simple measurements are not working. It must be in the Arduino, right? But all of the Arduinos?What is in common to the Arduino analog inputs, is that they generally have a SAR type ADC. These are ubiquitous because of their ability to provide lots of precision with high sampling rates in a small space. However, there are specific requirements for driving a SAR, as described in the large number of application notes and articles on the topic. When not driven correctly, the SAR produces "kickback" or aberrant readings. MCU manufacturers, faced with constraints in space, cost and power rails, take an approach that hides the kickback but lengthens the required sampling time (and increases the rate of forum postings). Here we show behaviors associated with the ADC in a few scenarios using spice models, and then we show how to manage the kickback in a way that also produces good measurements.

2. What is a SAR and why does it produce kickback?

SAR stands for successive approximation register. It has an input stage that samples a voltage using a capacitor, and a circuit that converts the voltage to digital using a comparator and a DAC plus an algorithm that does the successive approximation. They act one after the other, so there is an acquisition phase followed by a conversion phase. Kickback can appear as spikes or volage drops in the first phase, and failure to provide enough charge (or current) during the first phase can produce aberrant readings in the second stage. These behaviors trace back to the SAR input and how it interacts with what you attach to it. So that is where we will put our attention first, the SAR input and how it produces kickback.

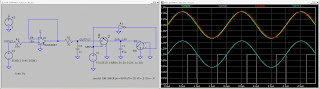

Input stage spice model

The figure below shows a simplified spice model for a SAR input. It comprises a capacitor C1, two switches S1 and S2, and a clock that drives the switches, modeled as a clocked pulse source V1. This is based on an application note on the Analog Devices website, "LTspice: Simulating SAR ADC Analog Inputs" by K Lokere and G Alsono, from 2017.

Sampling sequence

So, how does this work? Here are the steps relative to the clock pulse from V1. Please refer to the above figure.

Behavior with an ideal voltage source

Here is the spice model in action, using an an "ideal" voltage source. We just want to see the timing for right now. (We will show you both kinds of kickback after this.) The input is green, purple is the voltage on C1 and grey is the clock. Recall the three steps we listed above, S1 closes, C1 samples the voltage, S1 opens and S2 closes. We see the voltage on C1 rise abrubtly, match the input and then drop abruptly, and the input remains constant. But that's with an ideal voltage source that can sink and source whatever current it needs to maintains its voltage. So far, so good.

Thermistor, voltage errors

Now let's try a 10k thermistor. A typical setup is a voltage divider formed by the thermistor and a comparably valued resistor, as in the following. (Pretend one of the resistors is the thermistor.) Green is the source voltage, red is the voltage at the tap in the divider. and grey is the clock pulse. In the second figure, purple is the voltage on the SAR capacitor. Recall that in the actual ADC, the capacitor would be held at the voltage it reaches at the end of the acquisition phase and connected to the conversion circuit. In other words, the voltage at C1 attained at the end of the sampling period, is the voltage that gets converted to digital. And in this scenario, it is different from the voltage that you are trying to measure.

The problem:

One way to think of this is that there is not enough current available to charge the capacitor within the sampling interval.

In the first figure we see that the SAR input pulls down the voltage at the divider.

And in the second, we see the voltage on the capaciter has not risen to the input before the end of the sampling interval, i.e., at the trailing edge of the clock.

You can think of this as an RC network, and it is more or less the same idea.

A "hack":

The following is not a great idea in all situations.

But, let's say you are measuring a slow signal, and your ADC lets you set the length of the acquisition window.

And, let's say we want to recover within 1/2 of the acquisition window.

The time constant for the RC network formed by our 10k thermistor and 40pf SAR, is 10K x 40pf = 400 nsec.

So, if a 1% reading is okay, you need 4usec.

If you want 12 to 16 bits, you'll need something like 10usec.

But, not all ADC's will let you do that and even then, it might mean that you run your fast ADC as a not quite so fast ADC.

Another "hack", and sampling noise:

Choosing a SAR with a smaller capacitor might give you a shorter recovery time.

But there is a trade-off.

Sampling noise is fundamentally limited at 2kT/C (for a Nyquist rate switched capacitor network, SNR is V2C/4kT).

So making C small, makes noise bigger.

A take-away from this can be that

when choosing or designing for an ADC,

check the specs carefully including bandwidth, SNR and effective number of bits.

OPAMP Buffer, but voltage spikes

In some cases, a simple voltage follower might be sufficient to give you good readings from your ADC. Here is an example. In the spice model shown in the figure, we inserted an OPAMP follower between the thermistor and SAR input. Notice that there is still a negative spike (-0.25V) at the input of the OPAMP, and a large spike (-1.2V) at the input to the SAR. But the voltage recovers inside of 40nsec, in plenty of time for the conversion to digital to be accurate. The resistor R3 controls the size and timing; smaller resistor gives you faster recovery, but more ringing and larger spikes. I chose the resistor to be large enough to dampen the ringing in the SAR signal but still be fast enough for the length of this acquisition window.

We might call this a "work-around" rather than a complete solution. The spike on the input might be an issue if it disturbs the thing you are trying to measure. For some circuits, if the spike goes past -0.3V, it may even damage something though there is usually not a lot of current in it. Making R3 bigger to reduce the spike, might require a longer acquisition window and a sampling rate that is too slow for your application. Fortunately there is a better way, which we will get to in a moment.

Jumper wires

Jumper wires and solderless breadboards contribute impedance to the connection between the OPAMP and SAR. In this figure, we insert a small inductor, 0.1μH, perhaps about 4" of 24 awg wire. And, we switch over to a sinusoidal input. As before, we have input (green), output (red) before the inductor, and we add a trace for the input to the SAR (torquise) after the inductor. Offsets are added for clarity of presentation. The spike at the output from the OPAMP is still about 1.6V and now there is a much larger 2.6V spike on the signal seen by the SAR. Recovery is still fast comapred to the acquisition window. But, that may not be the case at higher frequencies and with longer wires.

3. The solution for a SAR, and how it works.

Capacitor as charge reservoir

Here is a solution that is recommended by the people who make the SAR ADCs. It looks like an RC network, but what it is doing is a little bit more sophisticated. First lets see the effect. We have input (green), output (red), sampling clock (grey) and, no more kickback! That small resistor 20 ohms, means that what is on the feedback loop is pretty similar to the output, so there really is no kickback to speak of in the OPAMP. There is a small almost neglibible phase shift. In the next paragraph we will show you what is happening, and then talk about how you design it.

Current flow, no more kickback

The follwing shows the current flowing through R1 (torquise) and C2 (red). We can see that charge for the SAR now comes from our charge reservoir C2. In the current flow through R1 we see a slow low amplitude feature following the narrow spike in C2. That is C2 being replenished for the next transient. Remember that charge is the integral of current.

And now, to be complete, here is probably one of the better ways to take measurements with an ADC. This is called and "instrumentation amplifier", or "InAmp" It has a differential input, and can have fantastic high impedance with very low noise. Even better than this, would be one with a differential output and with InAmp and ADC on the same board. There is a nifty one of those with high bandwidth, low noise and good dynamic range, and some other useful circuits for your lab here

4. Microcontroller analog input with built-in resistor.

Unfortunately, if you are using the analog input of a microcontroller (think Arduino, Teensy, etc.), you probably won't be able to use the above technique. This is because MCU makers typically insert a resistor in series with the switched sampling capacitor. This tames the kickback somewhat by limiting the current flow to the capacitor. But it also limits the benefit of an external charge reservoir or buffer. Let's understand the problem and then let's see what is the best way to treat it.

The following is from the NXP IMXRT datasheet (IMXRT1060CEC Rev. 3, 03/2022). Here we see a resistor RADIN in series with the switched sampling capacitor CADIN. The values range from a 5K to 25K. That limits the kickback, but it also pre-empts using an external charge reservoir or a buffer to act as a low impedance source to feed the sampling capacitor. It is a kind of partial "fool-proofing" at the expensive of turning it into a slower interface. For a 12 bit interface they are able to mitigate that somewhat by using a smaller capacitor.

Here is the worst case behavior, slow resistor with fast acquisition window. Note also the input is a divider with two 10 resistors (one is a thermistor) and the resistor in the sampling network 25K. It could be worse, the faster setting has 5K in the sampling network. Anyway, we see that it is a solid miss for reading the voltage correctly. So, what does it take to get good readings with the analog input for an MCU? Well, if you are using a 25K input, and you have time, you can try using the slowest setting on your ADC (if your MCU lets you control that). Here is what it looks like with the slowest setting with this MCU. A perhaps better way to do it, is to use an opamp buffer. The buffer presents a low impedance output so that you can use the smallest of the internal input resistances. And that is the best you can do with this particular MCU analog input.

5. Some concluding words and suggestions

In designing a circuit to drive a SAR type ADC, we want to achieve accurate voltage readings and we may want to limit spikes being sent back into what we attached to the SAR input. The capacitor that we added before the SAR input (C2) needs to be sufficiently large compared to the SAR capacitor (C1) so that it can be an adequate charge reservoir and the OPAMP has to provide sufficient current to replenish C2 through R1. The RC network comprising R1 and C2 can also serve as an anti-aliasing filter for the ADC. But there are tradeoffs as usual in an RC filter as well in the need to replenish C1 in a short time compared to the sampling window. All of this can be calculated, but it may be convenient to use a spice model to explore values for R1 and C2.

But, if you are using the analog input of an MCU, you might not have the above as an option. The source impedance should be small compared to the internal series resistor, or you can use an opamp buffer to isolate the source impedance and present a low impedance to the analog input. But to get a good voltage reading, you will still need to allow for a multiple of the time constant of the sampling capacitor and its series resistor.

Finally we want to mention that here we are treating the basic aspects of using a SAR type ADC. In the first cases we saw that if we wait long enough, we can make a better measurement. We solved some of that using an OPAMP buffer and then we showed the solution with an RC network, and we showed best options for an MCU analog input. But there are other sources of noise in a measurement, for example 1/f noise where waiting long enough does not help you make a better measurement. Some OPAMPS are more sensitive to 1/f noise and in general, the best answer involves correlated double sampling. But that will be the topic of another blog. Here we hopefully provided some insight into the prerequisite task of getting the ADC to work correctly and gives us a reliable result.

5. Professional instrumentation on a budget, the SPI Instrumentation Project and supporting open science: